LDPE

LDPE (low density polyethylene) is a soft, flexible, lightweight plastic material. LDPE is noted for its low temperature flexibility, toughness, and corrosion resistance. ExxonMobil™️ low-density polyethylene (LDPE) resins range from 0.919 to 0.928 g/cm³, making them suitable for a broad range of applications.

LLDPE

LLDPE (Linear Low-Density Polyethylene) is being used in extrusion coating applications where it helps protect the contents of liquid containers, primarily for paper and paperboard packaging. ExxonMobil™️ and ExxonMobil™️ NTX linear LLDPE resins offer an optimal balance of toughness and stiffness.

HDPE

HDPE (High Density Poly Ethylene) is one of the most versatile plastic materials around, ExxonMobil™️ HDPE resins offer a balance of processability, toughness, stiffness and environmental stress cracking resistance. This is one more way in which the ExxonMobil polyethylene business is helping deliver tomorrow's performance today.

MLLDPE

MLLDPE (Metallocene Linear Low-Density Polyethylene) is used in food and industrial packaging applications. These include multi-layer cast stretch film, agriculture greenhouse film, medium to heavy duty bags and lamination packaging film.

BOPP

BOPP films are used in food packaging and are replacing cellophane in applications such as snack and tobacco packaging due to favorable properties and low cost.

Pearlised BOPP

BOPP pearl film can be directly used for ice cream and other cold drinks packaging, can also be used for candy pillow packing, chocolate, soap protective packaging.

PET

PET (also abbreviated PETE) is short for polyethylene terephthalate, the chemical name for polyester. PET is a clear, strong, and lightweight plastic that is widely used for packaging foods and beverages, especially convenience-sized soft drinks.

Metallised Film

They offer the glossy metallic appearance of an aluminium foil at a reduced weight and cost. Metallised films are widely used for decorative purposes and food packaging, and also for specialty applications including insulation and electronics.

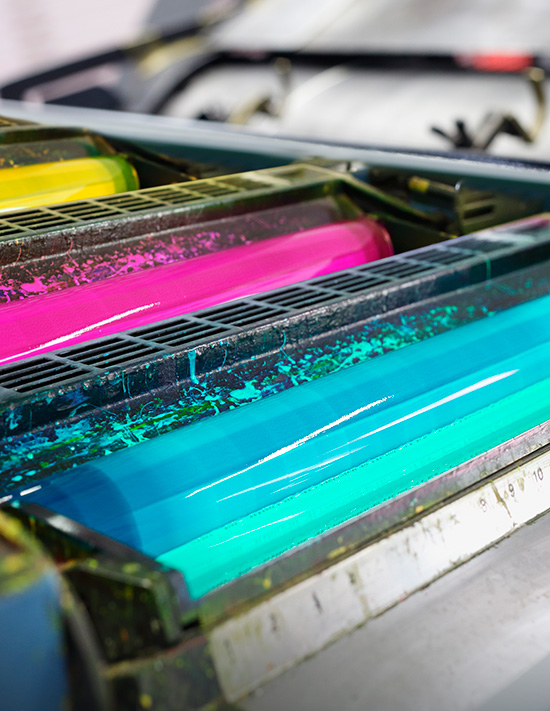

Polyamide Inks

These are superior to oil-based printing inks because they adhere to the surface of the material, while oil-based inks must be absorbed into the material.

PU Based Ink

PU Based Ink is based on a nitrocellulose and chlorine free polyurethane/acrylic binder system and is especially designed to meet the requirements of a broad range of high performance lamination applications.

EnBA

ExxonMobil™️ ethylene n-butyl acrylate (EnBA) copolymers adhere to a variety of polar substrates including paper, polyesters, ionomers, PVdC and unplasticized PVC.

EVA

Escorene™️ ethylene vinyl acetate (EVA) copolymers are used in extrusion film processes for applications including packaging, surface protection and greenhouse covers – and in photovoltaic cell encapsulation.

Bitumen Modifiers

Polybilt™️ bitumen modifiers are added to bitumen (asphalt) for improved performance, greater durability and easier processing.

Exact™️ Plastomers

Alpha olefin copolymers for flexible packaging, molded/extruded products, wire and cable, and foaming compounds.

EMA

The most thermally stable of all high-pressure PE copolymers, Optema™️ ethyl methyl acrylate (EMA) copolymers can be processed by extrusion coating lamination, blown/cast monolayer and coextruded films, injection molding, sheet or profile extrusion, blow molding and foam extrusion.